ABOUT SURENUT

THE TECHNOLOGY

What is the SureNut Analyser?

A one-pass QA system that measures shelf life, aflatoxin, moisture, colour, count per ounce and the 14 basic fault categories.

Surenut has developed an accurate Analyser that digitally assesses the physical categories plus reports accurate measurements for; colour, moisture, Free Fatty Acids and Aflatoxin B1.

In its early development, AI & Deep Learning software was utilised and perfect examples of each parameter were being captured. Test QA batches were run repeatedly to train Surenut's deep learning matrix to make calls more accurately, consistently and faster than people.

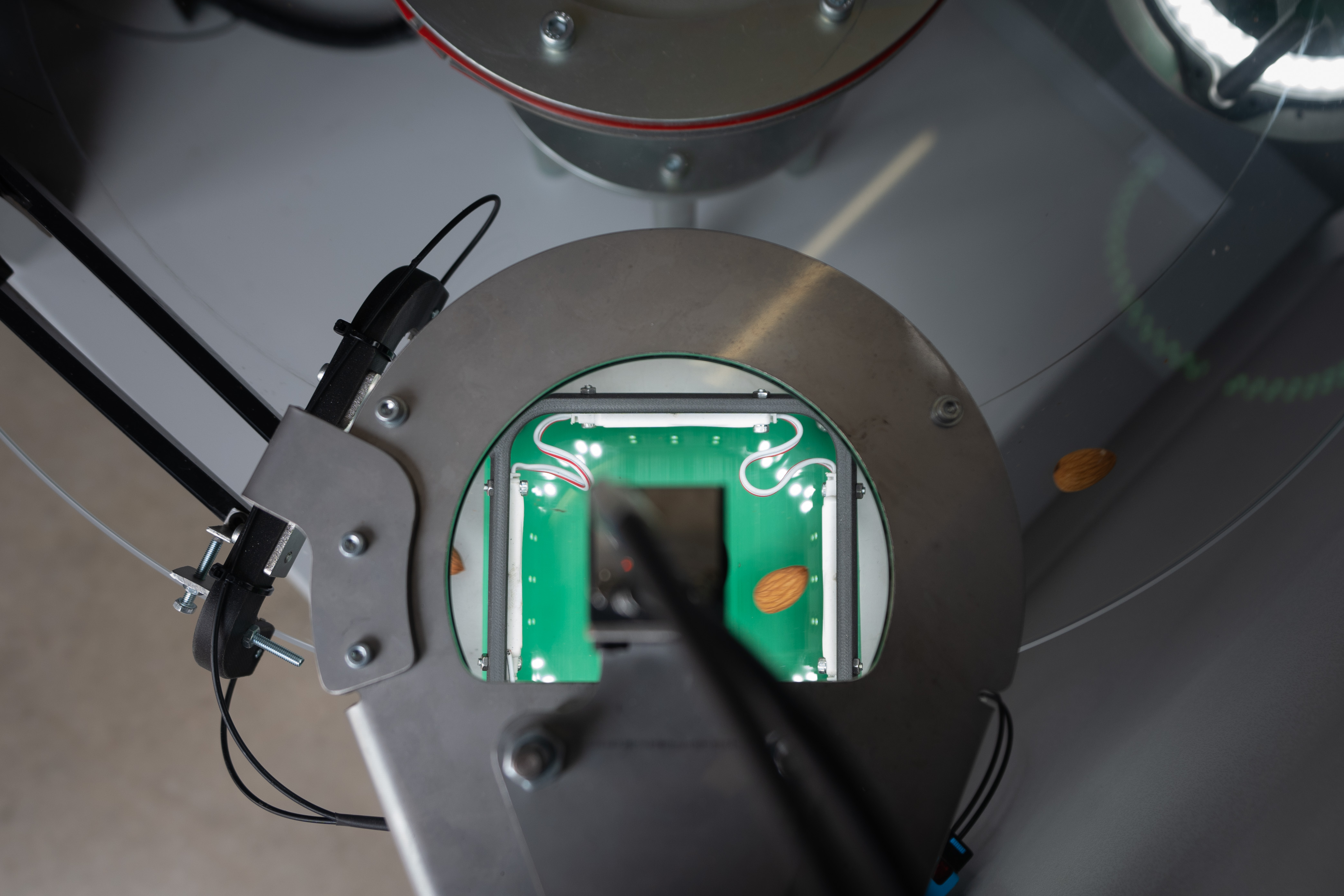

Sample products are fed onto a rotating glass plate viewed by RGB cameras under filtered light, analysing a 500g sample of Almonds.

Surenut has undertaken independent trials for the last two years to validate accuracy and develop a superior system that currently has the capability to;

- Analyse 500 almonds in a fraction of the time required by humans

- Measure 14 parameters achieving > 92% accuracy, reducing the high risk of errors that can occur in subjective human analysis

- ACI working consistently for each almond – reporting as an average for each sample or batch

- Worlds first Detection of aflatoxin with skin on

- Determine product shelf life through the accurate measurement of free fatty acid

- Unrivalled accuracy in the lab

It is important to note that current independent validation processes have a median accuracy of 75%. The faster cycling of QA samples at over 90% accuracy means the Surenut Analyser provides higher frequency of testing with increased product confidence.

Technology designed to get your product to the market faster than ever before

By having samples continuously bled from the main flow and analysed every 5–20 minutes, Surenut Analyser can communicate directly with each sorter and “adjust” the ejection rate of each almond fault – so that the batch is within customer specifications. Currently, a batch is analysed at the end of the run and out of spec product needs to be re-sorted.

The ability to have the Surenut Analyser operate alongside a cascade of three electronic sorters and routinely analyse a “bleed sample” from each sorter and communicate with each of those sorters to optimise their performance, adds unheard of inline gains. Analysis of the last sorter’s performance also reports the QA results for the batch.

The sensitivity of the analyser enables detection of defects that are not visible to the human eye, within the 14 parameters.

To read more about our research, testing and specifications to USDA & Australian almond QA processes, please download our product brochure.